DC gear motor is a compact and versatile electric motor that combines a DC motor with a gearbox. This marriage of technologies offers the best of both worlds: the high speed and torque of a DC motor and the precise speed control and increased torque output of a gearbox. They’re widely used in a vast array of applications, from powering robots and drones to controlling conveyor belts and operating automatic doors.

What is a DC Gear Motor?

At its core, a DC gear motor is a relatively simple yet powerful electro-mechanical device. It consists of two main components:

- DC Motor: This is the heart of the system, converting electrical energy into mechanical rotation. By applying a voltage across the motor’s terminals, it creates an electromagnetic field that causes the motor shaft to rotate. The speed of this rotation is directly related to the voltage applied.

- Gearbox: This is essentially a set of gears arranged in a specific configuration. The gearbox serves two primary functions: it reduces the speed of the motor shaft (often significantly) and increases the torque output. The gear ratio, determined by the number of teeth on each gear, dictates the amount of speed reduction and torque multiplication.

Imagine a DC motor spinning at a high speed but with relatively low turning force, like a race car engine. The gearbox acts like a transmission system, taking that high speed and converting it into a slower, more manageable rotation with significantly more power, similar to the low-gear setting in a car. This allows DC gear motors to tackle tasks that require both precise movement and the ability to overcome resistance.

How Does a DC Gear Motor Work?

The operation of a DC gear motor can be broken down into a series of steps:

- Electrical Input: When a DC voltage is applied to the motor’s terminals, it creates an electromagnetic field within the motor.

- Magnetic Force: This electromagnetic field interacts with the permanent magnets located inside the motor’s rotor (the rotating part). The interaction between these magnetic fields creates a force that causes the rotor to spin.

- Speed Regulation: The speed of the rotor is directly proportional to the applied voltage. By controlling the voltage, we can precisely control the speed of the motor shaft.

- Power Transfer: The rotating motor shaft transfers its energy to the input shaft of the gearbox.

- Gear Reduction: The gears within the gearbox mesh together, and the gear ratio determines how much the speed is reduced. For instance, a 10:1 gear ratio would translate to 10 rotations of the motor shaft for every 1 rotation of the output shaft.

- Torque Multiplication: As the speed is reduced, the gearbox also multiplies the torque output. Torque is essentially the twisting force of the motor shaft, and this increase allows the motor to handle heavier loads or overcome greater resistance.

- Output Rotation: The final output of the system is a slower-rotating shaft with a significant increase in torque compared to the original DC motor shaft.

Different Types of DC Gear Motors

DC gear motors come in a wide variety of configurations to suit diverse applications. Here’s a breakdown of some of the most common types:

- Brush DC Gear Motors: These are the most prevalent type, featuring brushes that make contact with the commutator on the motor shaft. They offer a good balance of performance, cost, and ease of control.

- Brushless DC Gear Motors (BLDC): These motors utilize electronic commutation instead of brushes, leading to higher efficiency, lower maintenance requirements, and longer lifespans. However, they tend to be more expensive than brush DC motors.

- Planetary Gear Motors: These motors employ a planetary gear arrangement, offering high torque output in a compact package. They’re often used in applications requiring high precision and smooth operation.

- Right Angle Gear Motors: These motors have an output shaft positioned at a 90-degree angle to the motor shaft, making them ideal for situations where space is limited or a right-angle rotation is needed.

- Worm Gear Motors: These motors utilize a worm gear and a worm wheel configuration, providing exceptionally high torque reduction and self-locking capabilities. They’re well-suited for low-speed, high-torque applications.

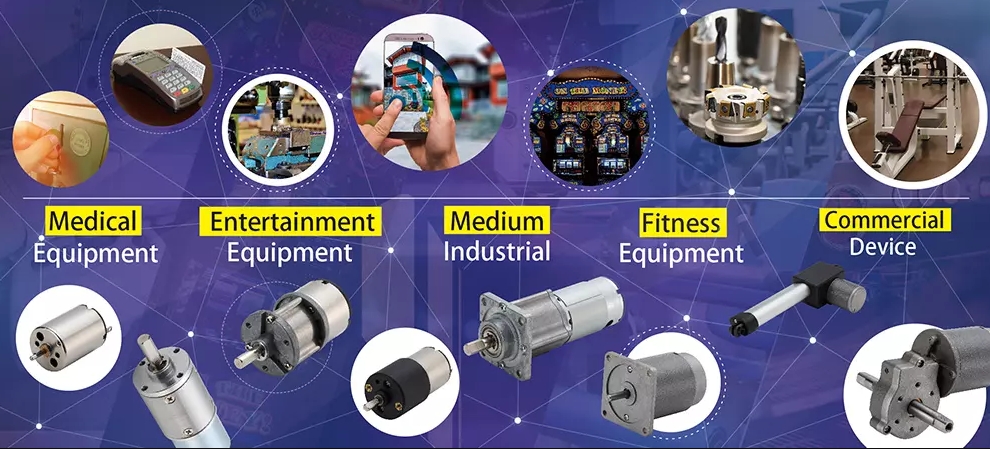

Applications of DC Gear Motors

| Application | Example |

| Automation Equipment | Conveyor belts, pick-and-place machines |

| Manufacturing | Assembly lines, material handling systems |

| Medical Devices | Dentists’ drills, surgical robots |

| Security Systems | CCTV cameras, automatic doors |

| Power Tools | Drills, screwdrivers, saws |

| Consumer Electronics | CD players, printers, massage chairs |

| HVAC Systems | Dampers, actuators |

| Agriculture | Irrigation systems, automated feeders |

| Transportation | Seat adjusters, window regulators |

Choosing the Right DC Gear Motor

Selecting the appropriate DC gear motor for your project requires careful consideration of several key factors. Here’s a table outlining some of the crucial parameters to evaluate:

| Factor | Description |

| Voltage Rating | The DC voltage the motor is designed to operate on (e.g., 12V, 24V) |

| Speed | The desired output speed of the motor shaft (typically in RPM) |

| Torque | The required torque output to handle the load (often specified in oz-in or lb-in) |

| Gear Ratio | The amount of speed reduction and torque multiplication needed |

| Motor Type | Brush DC, brushless DC, planetary, right angle, worm gear, etc. |

| Shaft Size | The diameter of the motor shaft (important for mounting and attaching components) |

| Duty Cycle | The percentage of time the motor will be running under load |

| Environmental Conditions | Operating temperature, humidity, and exposure to dust or liquids |

| Cost | Balancing performance requirements with budgetary constraints |

By carefully analyzing these factors, you can select a DC gear motor that perfectly aligns with your project’s specific needs.

Where to Buy DC Gear Motors

DC gear motors can be purchased from a variety of sources, including:

- Online Retailers: Major online retailers like Amazon and Digi-Key offer a wide selection of DC gear motors from various manufacturers.

- Electronics Distributors: Electronics distributors specializing in industrial automation components typically stock a comprehensive range of DC gear motors.

- Specialty Motor Stores: There are stores dedicated solely to electric motors, offering expert advice and a curated selection of DC gear motors.

- Manufacturer Websites: Many DC gear motor manufacturers sell directly through their websites, providing detailed specifications and technical support.

DC Gear Motor Suppliers

Among the many DC gear motor suppliers, one prominent company stands out:

- STEPPERONLINE has been specialized in stepper motors and drivers for over 17 years. They endeavor to create the best online platform for providing stepper motors, stepper motor drivers, and accessory products for companies and customers with varying skill levels. As a customer-oriented company, STEPPERONLINE has been offering high-quality, affordable products and exceptional customer service, which has been widely acclaimed by customers from over 30 countries. STEPPERONLINE is committed to providing a platform for more and more small and medium enterprises, hobbyists, and DIYers to obtain products they might not be able to get directly from factories, such as customized motors and discounted prices.

DC Gear Motor Pricing Ranges

The cost of a DC gear motor varies depending on several factors, including:

- Motor Type: Generally, brushless DC motors are more expensive than brush DC motors.

- Power Rating: Motors with higher voltage ratings and torque outputs tend to be more costly.

- Gear Ratio: More complex gearboxes with higher gear ratios may increase the price.

- Features: Additional features like encoders or speed controllers can add to the cost.

- Brand & Quality: Well-known brands and motors with superior quality materials typically command a higher price point.

Here’s a general estimate of DC gear motor pricing ranges:

- Low-Cost: $5 – $20 (Simple brush DC motors with low power ratings)

- Mid-Range: $20 – $100 (Brush and brushless DC motors with moderate power ratings and features)

- High-End: $100+ (High-power brushless DC motors, planetary gear motors, and specialty motors)

Pros and Cons of DC Gear Motors

Pros:

- Versatility: DC gear motors offer a wide range of speed and torque combinations, making them suitable for diverse applications.

- Controllability: The ability to regulate both speed and torque allows for precise control over machine movements.

- Durability: Many DC gear motors are built to withstand demanding environments and continuous operation.

- Cost-Effectiveness: Depending on the required power and features, DC gear motors can be a cost-efficient solution for various applications.

Cons:

- Complexity: Compared to simpler DC motors, gear motors have additional mechanical components that require maintenance and can be prone to wear and tear.

- Heat Generation: Under high loads, DC gear motors can generate heat, necessitating proper heat dissipation strategies.

- Noise: Brushed DC gear motors can be noisy, while BLDC motors generally operate quieter but may require additional noise reduction measures for some applications.

Choosing the right DC gear motor requires a careful balance of these pros and cons to ensure it aligns with your project’s specific needs.

FAQ on DC Gear Motors

In this FAQ section, we’ll address some of the most commonly asked questions regarding DC gear motors:

Q: What is the difference between a DC motor and a DC gear motor?

A: A DC motor is the core electric motor component that converts electrical energy into rotation. A DC gear motor combines a DC motor with a gearbox, offering reduced speed and increased torque output compared to the standalone motor.

Q: How do I control the speed of a DC gear motor?

A: The speed of a DC gear motor is primarily controlled by regulating the voltage applied to the motor. This can be achieved using a simple DC power supply with variable voltage control or a dedicated motor controller that offers more advanced features like speed regulation and direction control.

Q: Which type of DC gear motor is right for my project?

A: The ideal DC gear motor for your project depends on various factors like the required speed, torque, voltage rating, and environmental conditions. By carefully considering these parameters and referring to the “Choosing the Right DC Gear Motor” section earlier, you can make an informed decision.

Q: Where can I find technical specifications for DC gear motors?

A: Most DC gear motor manufacturers provide detailed technical specifications on their websites or datasheets. These specifications typically include information on voltage rating, speed, torque, gear ratio, shaft size, and dimensional drawings.

Q: What are some safety precautions to consider when using DC gear motors?

A: Here are some essential safety practices:

- Always follow the manufacturer’s instructions for installation and operation.

- Use a voltage source that matches the motor’s rating.

- Provide proper ventilation or heat sinking to prevent overheating.

- Securely mount the motor to prevent accidents due to loose components.

- Disconnect the power source before performing any maintenance or repairs.

By following these guidelines, you can ensure the safe and effective operation of your DC gear motor.

I hope this comprehensive guide has empowered you with a newfound understanding of DC gear motors. These versatile and powerful devices play a crucial role in various applications, and by carefully considering the factors outlined above, you can select the perfect DC gear motor to elevate your next project.

-3-200x160w.jpg)

-1-3-250x250.jpg)